顎式破碎機 / 制砂機 / 洗砂機 / 篩沙機 / 移動破碎機

15038196798

文件下載 | ||

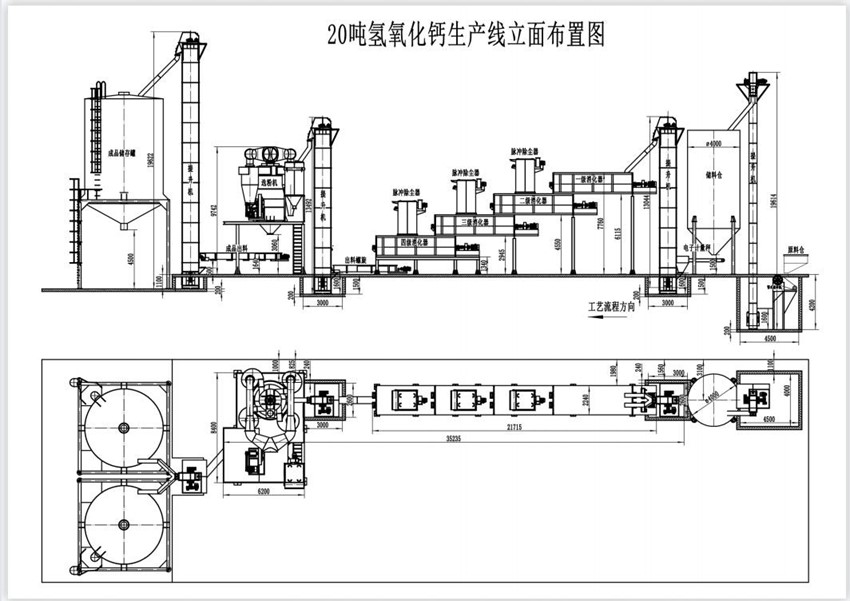

| 石灰立窯氫氧化鈣生產線技術方案 Technical scheme of calcium hydroxide production line in lime shaft kiln | |

| 電爐安裝工程量清單 Electric furnace installation works list | |

2* 150t 無煙煤石灰窯設計技術方案及投資概算

2* 150t Anthracite Lime Kiln Design Technical Scheme and investment estimates

(briefly)

貴公司要求兩套日產 150 噸石灰生產線,我建議用兩臺 200M3 無煙煤豎窯完成,具體方案及概算如下:

1. Brief description:

Your company requires two sets of lime production lines with a daily output of 150 tons. I propose to use two sets of 200M3 anthracite shaft kilns to complete the production. The specific plans and estimates are as follows:

1. 窯型為圓型豎窯,單窯容積 220m3有效容積 200m3爐體總高度約 28M 左右。

2. 單窯產量:150—155t/日

3. CaO>80%以上,生過燒率 9%以下。

4. 無煙煤消耗量 145kg/t.灰。

5. 單臺窯煙氣塵總量 15000-20000Nm3/h 左右。

6. 經除塵凈化后煙氣排放濃度<30mmg。

Two . Basic parameters and indicators

The kiln type is a circular shaft kiln with a single kiln volume of 220m3 and an effective volume of 200m3. The total height of the furnace body is about 28M.

Single kiln output: 150—155t/day

CaO>80% or more, the raw overburn rate is less than 9%.

Anthracite consumption 145kg/t. ash.

The total amount of flue gas and dust in a single kiln is about 15000-20000Nm3/h.

After dust removal and purification, the emission concentration of flue gas is less than 30mmg.

1.石灰石; 入窯 粒度 40-80mm,<40mm>80mm<10%。

2.煅燒溫度 900-1200℃。

無煙煤熱值>6000 大卡/Nm3;

3.無煙煤粒度 5-15mm,水分≤8%

Three,Raw fuel conditions:

Limestone; kiln particle size 40-80mm, <40mm>80mm<10%.

The calcination temperature is 900-1200℃.

Anthracite calorific value>6000 kcal/Nm3;

Anthracite particle size 5-15mm, moisture ≤8%

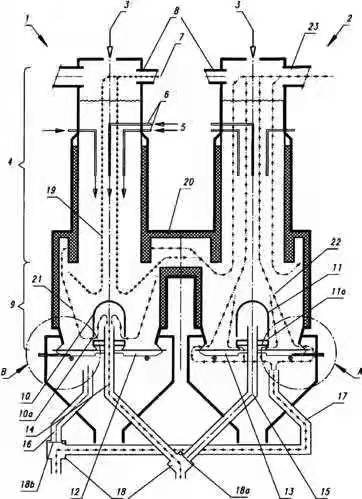

無煙煤石灰窯主體外型為園形豎窯(內部爐體為Φ2.5*m 圓形結構)主要有窯體、上料斜橋、料車、雙向密封布料裝置、窯中段安裝有偏火控制系統,窯下有助燃風機、冷卻風機、窯內安裝有概率風帽窯外安裝有卸灰裝置、抽煙除塵和溫度儀表及電器控制部分等幾部分組成。爐體為金屬殼,內砌耐火磚和保溫材料另有計量系統和溫度控制系統部分組成。

Four. Main structure of 200M3 shaft kiln

The main body of the anthracite lime kiln is a circular shaft kiln (the inner furnace body is a Φ2.5*m circular structure), which mainly includes a kiln body, a feeding inclined bridge, a feeding truck, a two-way sealing and distributing device, and a partial fire control installed in the middle of the kiln. The system consists of a combustion-supporting fan, a cooling fan under the kiln, a probability air cap installed in the kiln, an ash unloading device, a smoke and dust removal device, a temperature instrument and an electrical control part installed outside the kiln. The furnace body is a metal shell, and the inner refractory bricks and insulation materials are also composed of a metering system and a temperature control system.

經篩分處理后的合格石灰石原料和無煙煤經過計算機控制的計量系統按一定的比例配合,共用一套上料系統,由卷楊機拉動料車經斜橋至窯頂經分料倉進入兩個窯頂布料裝置(專利號 ZL20110307893.6)布入窯內。每座窯在窯體煅燒段周邊,裝有偏火控制系統(專利號 ZL201120307918.2),石灰石經上層燃燒器煅燒在煅燒帶上段基本完成煅燒分解,二層補充空氣主要補充中心部位的部分欠燒和增加石灰活性。石灰石在自重作用下的下降過程中,經過復雜的熱交換分解和脫炭反應,并伴隨著石灰石的晶粒發育成長過程完成煅燒,到冷卻帶被送入窯內的風冷風冷卻, 助燃風經窯內冷卻余熱換熱助燃風送入窯內重新助燃,(專利號 ZL20112037894.0)燒成的石灰由園盤出來機和兩段出灰閥在始終保持爐內密封狀態下經卸出窯外出灰皮帶機上送至成品灰倉。同時窯頂煙塵由抽風機將煙塵引入(重力)旋風除塵和水膜(脫硫)除塵系統對煙塵凈化煙塵濃度≤30mg 達到國家要求的環保標準排入大氣。

Five. Brief description of the process

After screening, the qualified limestone raw materials and anthracite coal are matched in a certain proportion by the computer-controlled metering system, and share a set of feeding system. The kiln top distribution device (patent number ZL20110307893.6) is distributed into the kiln. Each kiln is equipped with a partial fire control system (Patent No. ZL201120307918.2) around the calcination section of the kiln body. The limestone is calcined by the upper burner in the upper section of the calcination zone to basically complete the calcination and decomposition. Burn and increase lime activity. During the descending process of limestone under the action of its own weight, it undergoes complex heat exchange decomposition and decarbonization reactions, and is calcined along with the development and growth of limestone grains. In the cooling zone, it is cooled by the air-cooled air sent into the kiln, and the combustion-supporting air After cooling the residual heat in the kiln, the combustion-supporting air is sent into the kiln for re-combustion. The outgoing ash belt conveyor is sent to the finished ash warehouse. At the same time, the smoke from the top of the kiln is introduced into the (gravity) cyclone dust removal and water film (desulfurization) dust removal system by the exhaust fan.